Grease Traps vs. Interceptors

Disposing of fats, oils and grease (FOG) is a delicate process requiring the right tools and methods. While grease traps and grease interceptors have considerable differences, they’re essential in any business or facility that needs to get rid of FOG properly. Learn more about grease traps and grease interceptors and how they differ below.

What Is a Grease Trap?

A grease trap helps appropriately dispose of FOG in various facilities like restaurants. These traps are essential because they ensure FOG from wastewater doesn’t clog sewers and septic tanks. A grease trap fits under the facility’s kitchen sink and serves industries with FOG flow rates between 10 and 50 gallons. Often, grease traps are a requirement by local ordinances for the protection of sewer systems.

How Does a Grease Trap Work?

A grease trap works by trapping FOG from wastewater when it flows down the drain of the kitchen sink. Fats, oils and grease solidify in the trap and float to the surface. Then, the wastewater flows through the rest of the system toward its next destination — likely a municipal wastewater treatment center — ensuring no FOG is present to harm the sewer system.

What Is a Grease Interceptor?

Compared to grease traps, grease interceptors are FOG waste removal systems that serve the same purpose of removing FOG from wastewater on a larger scale. These systems are installed underground outside of facilities in easily accessible locations. Businesses like restaurants, cafeterias and bakeries with FOG flow rates of more than 50 gallons require grease interceptors.

Just like their smaller alternatives, grease interceptors are essential for businesses to comply with local ordinances and protect their plumbing systems.

How Does a Grease Interceptor Work?

The purpose of a grease interceptor is the same as that of a grease trap but on a larger scale. In a grease interceptor, wastewater flows through the system and collects in a tank, where the FOG separates from the wastewater — any solids sink to the bottom of the container, and the grease floats to the top, leaving the cleared water behind. Then, that water flows through a connecting pipe into a separate container, and can move freely through the sewer system.

What is the Differences Between Grease Traps and Grease Interceptors?

While grease traps and interceptors serve the same purpose, they do so on different scales and have a few other key differences between them. Here are the main differences:

Material

Grease trap units are usually made from materials like steel and plastic. Grease interceptors use stronger materials like fiberglass and cement so they can withstand harsh weather conditions like storms and hail. Grease traps can be less durable than interceptors and require replacement if they’re cracked or rusted.

Size

Grease traps are small units and can be the size of a small box, depending on the restaurant’s FOG flow rate. Grease interceptors are larger and can be the size of a mini-fridge with a holding capacity of over 500 gallons.

Smaller facilities like coffee shops that have lower FOG rates likely only require a grease trap. In contrast, large restaurants or bakeries may require grease interceptors to match their higher FOG rates.

Flow Rate

Businesses use grease traps or inceptors depending on their average grease use. For example, businesses disposing of less than 10-15 gallons of grease per minute likely require a grease trap. Facilities that deal with more significant grease — more than 15 gallons per minute — have plumbing systems and drains that can handle large FOG volumes, meaning they require grease interceptors.

Location

Grease traps are small enough to install under kitchen sinks. Grease interceptors are larger, requiring businesses to install them under their facilities. Local ordinances may have rules and regulations regarding the placement of grease interceptors.

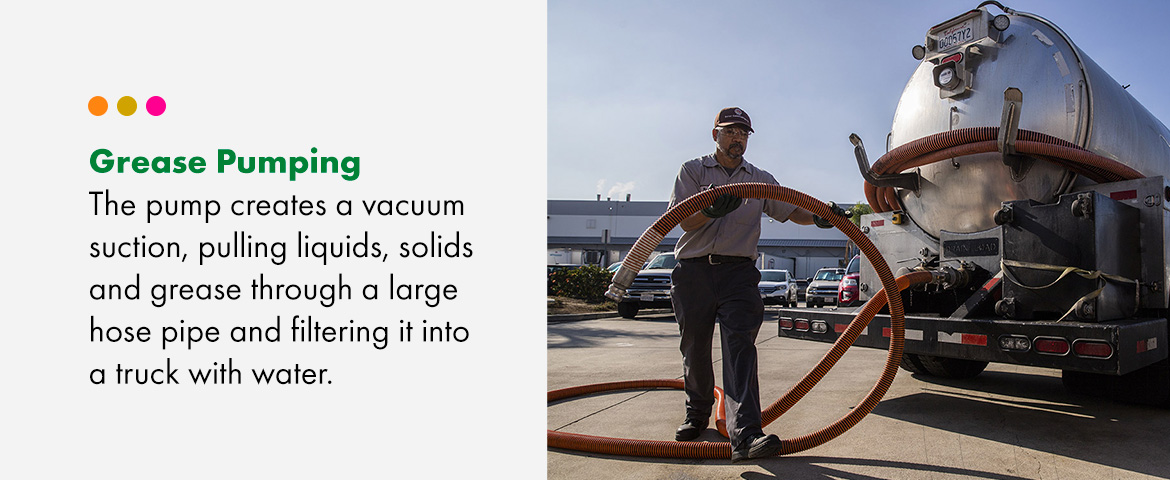

Grease Pumping

Businesses with grease interceptors require professional and licensed cleaning services. Cleaning companies use a pump to clean the grease trap. The pump creates a vacuum suction, pulling liquids, solids and grease through a large hose pipe and filtering it into a truck with water. After pumping, any remaining water waste is swept away.

Cleaning Frequency

Grease traps can accumulate grease quickly, requiring frequent cleaning. Grease interceptors can hold larger volumes of FOG and require cleaning less frequently than grease traps. Depending on grease volumes, businesses can have grease traps cleaned weekly or monthly. Grease interceptor cleaning can range from monthly to quarterly or whenever the device becomes one-fourth full of grease/solids.

Do You Need a Grease Trap or a Grease Interceptor?

Here are some factors to consider when deciding between a grease trap or grease interceptor for your business:

- Flow capacity: Grease traps have a lower FOG capacity than grease interceptors. Consider your wastewater levels and the unit type needed for your facility’s FOG flow rates. You want to ensure that you follow government regulations and protect your pipes and septic system from FOG buildup.

- Maintenance regularity: You have to clean a grease trap more frequently than an interceptor, requiring regular expert cleaning services. Grease interceptors take longer to fill up and require specialized cleaning services less often than grease traps.

- Installation method: Consider your building and whether you have space for a grease trap under your kitchen sink. You also want to consider your kitchen’s placement, as grease traps can have unpleasant odors. You require a bigger underground or outdoor space for grease interceptor installation. Consider if your building size and design can accommodate a grease interceptor.

- Water pressure: Grease traps can be more suited to businesses with low water pressure, as they produce less wastewater. Grease interceptors work better for businesses with high FOG rates.

Learn About Our Grease Removal Services

Managing your wastewater and preventing fats, oils and grease from clogging sewer and septic systems is essential. A grease trap or interceptor can help your business properly dispose of FOG without harming your plumbing system.

Baker Commodities offers Total Grease Management™ services that follow and comply with your local municipality’s FOG disposal regulations and environmental standards. We can pump and clean your grease traps or interceptor system routinely, allowing you to properly and safely get rid of FOG and wastewater.

Our services can help preserve your drains, improve your company’s environmental impact and dispose of FOG in the safest and most environmentally friendly way possible. Contact us today to learn more about how we can assist your facility.